NLS Series Inflow Pressure Screen

| Type | NLS0.6 | NLS1 | NLS1.5 | NLS2 | NLS3 |

| Screen Area (m2) | 0.6 | 1 | 1.5 | 2 | 3 |

| Concentration of Input Pulp(%) | 0.4-0.8 | ||||

| Capacity (Screen Hole) (t/d) | 30-60 | 70-130 | 110-160 | 140-260 | 250-400 |

| Capacity (Screen Slot) (t/d) | 25-45 | 55-80 | 80-120 | 100-160 | 150-300 |

| Pressure of Inflow Pulp(mpa) | 0.1-0.4 | ||||

| Motor Power (kw) | 7.5-15 | 22 | 30 | 37 | 45 |

| Type | NLS4 | NLS5 | NLS6 | NLS7 |

| Screen Area (m2) | 4 | 5 | 6 | 7 |

| Concentration of Input Pulp(%) | 0.4-0.8 | |||

| Capacity (Screen Hole) (t/d) | 260-520 | 350-600 | 420-700 | 500-900 |

| Capacity (Screen Slot) (t/d) | 180-320 | 220-400 | 260-480 | 350-600 |

| Pressure of Inflow Pulp(mpa) | 0.1-.0.4 | |||

| Motor Power (kw) | 55 | 75 | 90 | 110 |

| Type | NLS8 | NLS9 | NLS10 | NLS11 |

| Screen Area (m2) | 8.5 | 9.6 | 10.5 | 12 |

| Concentration of Input Pulp(%) | 0.4-0.8 | |||

| Capacity (Screen Hole) (t/d) | 600-1120 | 700-1200 | 770-1300 | 840-1400 |

| Capacity (Screen Slot) (t/d) | 400-720 | 440-800 | 480-880 | 520-960 |

| Pressure of Inflow Pulp(mpa) | 0.1-.0.4 | |||

| Motor Power (kw) | 110 | 132 | 160 | 160 |

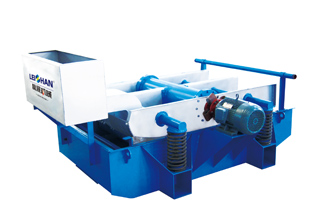

NLS series inflow pressure screen is a continuing screening equipment under the fully closed position with pressure.

When works, the pulp enters into the outside of screen drum along the tangent direction through the pulp pipe. Qualified pulp enter into screen drum through the sieve seam (hole), with the help of pressure difference between inside and outside of screen drum, then come out through the pulp pipe. The pulp and impurities which can not through the sieve seam (hole) fall down to the bottom, and come out from the discharge pipe.

Rotating blade outside the screen drum can produce a moderate pressure, which improves the circulation flow of pulp, its tail will produce a negative pressure, which has an effect of backwash sieve seam (hole). It can prevent the sieve seam (hole) congestion, and pulp can smooth enter through the sieve screening (hole) from the surface constantly, which ensures the continuous operation.

Offering comprehensive technical and business consultation services;

Offering comprehensive technical and business consultation services;

Proposing the most suitable scheme and equipment for our clients;

Designing and fabricating targeted products according to the special requirements of clients;

Training periodically high qualified service technician.

BFW Chain Conveyor

BFW Chain Conveyor

ZG Drum Pulper

ZG Drum Pulper

D Type Hydrapulper

D Type Hydrapulper

Mid Consistency Pressure Screen

Mid Consistency Pressure Screen

NLS Inflow Pressure Screen

NLS Inflow Pressure Screen

ZDP Double Disc Refiner

ZDP Double Disc Refiner

JB Chest Agitator

JB Chest Agitator

ZDFD Fiber Separator

ZDFD Fiber Separator

High Density Cleaner

High Density Cleaner

ZM Conical Claflin Refiner

ZM Conical Claflin Refiner

Kraft Liner Board Machine

Kraft Liner Board Machine

KH Low Density Cleaner

KH Low Density Cleaner

Corrugated Paper Machine

Corrugated Paper Machine

PZ Reject Separator

PZ Reject Separator

ZSK Vibrating Screen

ZSK Vibrating Screen

You can get the price list and a Leizhan representative will contact you within one business day.