1. The machine can screen pulp normally under quite high consistency(2.5-4%). It reduces the amount of water cycle and system energy consumption in production process.

2. Heavy impurities discharge pipe makes sure the screen basket runs safely.

3. Advanced structure, sturdy and durable, convenient disassembly and assembly, low energy consumption, less loss of fiber.

4. Easy to operate, less malfunctions for continuous working, less maintenance cost.

5. Automatic oil injection device can reduce maintenance.

6. Seal water flow automatic detection alarm device makes sure the system runs safety.

7. Interlock system ensures the service life of equipment.

| Model NO | ZNS0.3 | ZNS0.6 | ZNS0.9 | ZNS1.2 | ZNS1.5 |

| Screen Area (m2) | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 |

| Sieve hole size (mm) | Φ1.6-Φ3.5 | ||||

| Seam Size (mm) | 0.10-0.55 | ||||

| Screen Hole (T/D) | 50-80 | 90-160 | 135-250 | 180-320 | 200-380 |

| Screen Slot (T/D) | 30-50 | 60-100 | 90-150 | 120-190 | 140-230 |

| Inlet pulp consistency (%) | 1-4 | ||||

| Motor Power (Kw) | 22-55 | 30-75 | 37-90 | 45-110 | 55-132 |

| Model NO | ZNS2 | ZNS2.5 | ZNS3 | ZNS4 | ZNS6 |

| Screen Area (m2) | 2 | 2.5 | 3 | 4 | 6 |

| Sieve hole size (mm) | Φ1.6-Φ3.5 | ||||

| Seam Size (mm) | 0.10-0.55 | ||||

| Screen Hole (T/D) | 260-500 | 300-600 | 400-700 | 500-1000 | 800-1500 |

| Screen Slot (T/D) | 200-300 | 250-400 | 300-450 | 350-730 | 500-1100 |

| Inlet pulp consistency (%) | 1-4 | ||||

| Motor Power (Kw) | 75-160 | 90-200 | 90-220 | 132-280 | 250-400 |

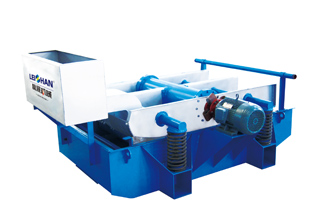

Pressure screen under the rotating function of drum sieve and rotating cylinder and centrifugation effect. The machine will separate the qualified pulp and non-qualified pulp. It consist of cylinder, cylinder cover, sieve drum, rotary cylinder, base and transmission parts, etc.

Offering comprehensive technical and business consultation services;

Offering comprehensive technical and business consultation services;

Proposing the most suitable scheme and equipment for our clients;

Designing and fabricating targeted products according to the special requirements of clients;

Training periodically high qualified service technician.

BFW Chain Conveyor

BFW Chain Conveyor

ZG Drum Pulper

ZG Drum Pulper

D Type Hydrapulper

D Type Hydrapulper

Mid Consistency Pressure Screen

Mid Consistency Pressure Screen

NLS Inflow Pressure Screen

NLS Inflow Pressure Screen

ZDP Double Disc Refiner

ZDP Double Disc Refiner

JB Chest Agitator

JB Chest Agitator

ZDFD Fiber Separator

ZDFD Fiber Separator

High Density Cleaner

High Density Cleaner

ZM Conical Claflin Refiner

ZM Conical Claflin Refiner

Kraft Liner Board Machine

Kraft Liner Board Machine

KH Low Density Cleaner

KH Low Density Cleaner

Corrugated Paper Machine

Corrugated Paper Machine

PZ Reject Separator

PZ Reject Separator

ZSK Vibrating Screen

ZSK Vibrating Screen

You can get the price list and a Leizhan representative will contact you within one business day.