UV Series Up Flow Pressure Screen

1. Adopt up-flow structure: pulp inflow from bottom, heavy impurities are discharged from bottom and light impurities from top.

2. It shortens the dwell time of impurities in the screening area and avoid the abrasion to rotor and screen basket. So prolong the rotor and screen basket service life.

| Type | UV0.5 | UV1.2 | UV2.0 | UV3.0 | UV4.0 | UV5.0 |

| Area of Screen(m2) | 0.5 | 1.2 | 2.0 | 3.0 | 4.0 | 5.0 |

| Concentration of inflow and Output pulp(%) | 0.2-5.0 | |||||

| Size of Screen slot(mm) | 0.15-0.55 | |||||

| Size of Screen hole(mm) | 1.2-5.0 | |||||

| Production Capacity(t/d) | 20-30 | 40-60 | 80-100 | 100-250 | 160-450 | 200-500 |

| Equipping Power(kw) | 22/37 | 45/75 | 75/110 | 90/132 | 160/220 | 185/315 |

Offering comprehensive technical and business consultation services;

Offering comprehensive technical and business consultation services;

Proposing the most suitable scheme and equipment for our clients;

Designing and fabricating targeted products according to the special requirements of clients;

Training periodically high qualified service technician.

BFW Chain Conveyor

BFW Chain Conveyor

ZG Drum Pulper

ZG Drum Pulper

D Type Hydrapulper

D Type Hydrapulper

Mid Consistency Pressure Screen

Mid Consistency Pressure Screen

NLS Inflow Pressure Screen

NLS Inflow Pressure Screen

ZDP Double Disc Refiner

ZDP Double Disc Refiner

JB Chest Agitator

JB Chest Agitator

ZDFD Fiber Separator

ZDFD Fiber Separator

High Density Cleaner

High Density Cleaner

ZM Conical Claflin Refiner

ZM Conical Claflin Refiner

Kraft Liner Board Machine

Kraft Liner Board Machine

KH Low Density Cleaner

KH Low Density Cleaner

Corrugated Paper Machine

Corrugated Paper Machine

PZ Reject Separator

PZ Reject Separator

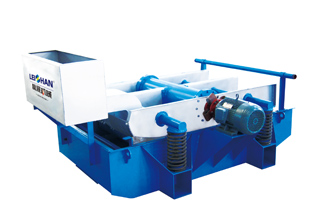

ZSK Vibrating Screen

ZSK Vibrating Screen

You can get the price list and a Leizhan representative will contact you within one business day.